- Description

- Customizations

- Reviews (0)

Description

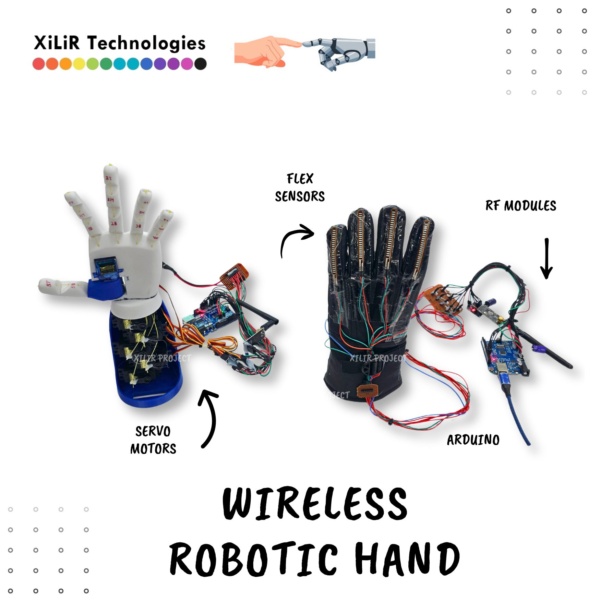

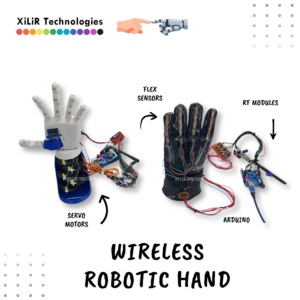

Wireless Gesture Controlled Robotic Hand Kit using Arduino and nRF Module – 3D Printed with Flex Sensor Glove

🧠 Introduction

The concept of robotic hands dates back to the early development of industrial robotics in the 1950s and 60s. Initially designed for repetitive factory work, robotic manipulators evolved from simple grippers to sophisticated prosthetic hands mimicking human anatomy. The first electrically actuated prosthetic hand was developed in the 1980s, and with the rise of microcontrollers like Arduino, affordable DIY versions became popular among researchers and students alike.

According to the World Health Organization (WHO), over 35 million people globally require prosthetic or orthotic devices. Meanwhile, in the industrial sector, robotic hands are vital for tasks demanding precision, safety, and repetition. Smart robotic prosthetics and gesture-controlled manipulators are rapidly bridging the gap between human intention and machine execution — especially in medical, military, and space exploration sectors.

This project uses a 3D-printed robotic hand with six servo motors — five MG995/MG996 for each finger and one 9g servo inside the thumb for intricate motion. The control glove is equipped with five flex sensors (one for each finger), interfaced through voltage divider circuits using 10k resistors, connected to an Arduino UNO or Nano. Real-time data is transmitted wirelessly using nRF24L01+ modules (with PA+LNA version offering up to 1 km range), allowing seamless gesture replication between the user’s hand and the robotic hand.

Gesture-controlled robotic hands are revolutionizing fields where precision and remote control are critical. From aiding amputees with low-cost prosthetics to enabling hazardous environment operations (like bomb defusal or toxic zone sampling), this technology is creating practical, affordable, and scalable robotic solutions.

🎯 Objectives

-

To develop a wireless robotic hand that mimics human gestures in real time.

-

To use flex sensors on a glove for detecting finger movements.

-

To transmit gesture data wirelessly using nRF24L01 modules.

-

To control a 3D-printed hand using Arduino and servo motors for each finger.

Components Used:

| S.No | Component Name | Quantity | Description |

|---|---|---|---|

| 1 | Arduino UNO / Nano | 2 | One for glove transmitter, one for robotic hand receiver |

| 2 | nRF24L01+ Module (with Antenna) | 2 | Long-range 2.4GHz RF modules (1 km range with PA+LNA) for wireless control |

| 3 | Flex Sensors | 5 | Mounted on glove, detect finger bending (gesture input) |

| 4 | 10kΩ Resistors | 5 | Used in voltage divider circuit with each flex sensor |

| 5 | MG995 / MG996 Servo Motors | 5 | High torque servos, used for each finger movement of robotic hand |

| 6 | 9g Servo Motor | 1 | Compact servo for thumb articulation inside the robotic palm |

| 7 | 3D-Printed Robotic Hand Frame | 1 | Custom-designed and printed hand for mounting servos and strings |

| 8 | Battery / Power Supply | 1 | Powering servos (separate from Arduino to avoid brownouts) |

| 9 | Jumper Wires & Breadboard | As req. | For circuit connections and prototyping |

| 10 | Glove (Fabric or Soft Base) | 1 | Worn by user, holds flex sensors and transmitter module |

| 11 | Servo Extension Wires / Strings | As req. | For connecting servo to finger tips of robotic hand |

Components Used:

Arduino UNO/Nano (×2),

nRF24L01+ Modules with Antenna (×2),

Flex Sensors (×5), 10kΩ Resistors (×5),

MG995/MG996 Servo Motors (×5),

9g Servo Motor (×1),

3D-Printed Robotic Hand Frame (×1)

, Battery/Power Supply (×1),

Jumper Wires & Breadboard (as required),Add product gallery images

Glove (×1),

Servo Extension Wires/Strings (as required).

⚙️ Working Principle

The project operates on the concept of real-time gesture capture and wireless transmission using Arduino-based control systems. The user wears a glove equipped with flex sensors that detect finger movements. These sensor readings are processed and transmitted via nRF24L01+ RF modules to the receiving end, which drives a servo-motor-actuated 3D-printed robotic hand to mimic the exact finger gestures.

🔹 1. Gesture Detection through Flex Sensors

-

Each finger of the glove has a flex sensor, which changes resistance when bent.

-

These resistance changes are passed through a voltage divider circuit (with 10kΩ resistors) to convert into readable analog voltages.

-

The Arduino Nano (Transmitter) reads these voltages via its analog input pins and maps them to servo motor angles (e.g., 0° to 180°).

-

This mapping ensures that the degree of finger bend is proportional to the rotation of the corresponding servo motor in the robotic hand.

🔹 2. Data Transmission using nRF24L01

-

The mapped values (one for each finger) are structured into a data packet.

-

Using SPI communication, these packets are sent wirelessly via the nRF24L01+ module.

-

This module, equipped with a PA+LNA antenna, offers a reliable communication range of up to 1 km (in open space).

-

The transmitter and receiver must be synchronized to operate on the same communication address and frequency channel.

🔹 3. Robotic Hand Control using Servo Motors

-

On the receiving side, an Arduino UNO is connected to an nRF24L01 module.

-

The Arduino continuously listens for incoming data packets and decodes them.

-

Each decoded value is sent to a corresponding servo motor (5 MG995/MG996 for fingers + 1 small 9g servo for thumb).

-

The servos rotate to angles equivalent to the detected finger movements, achieving accurate, real-time gesture replication.

🔹 4. Mechanical Setup and Synchronization

-

The 3D-printed hand structure is designed to hold each servo in a way that it can pull or push tendons (strings or wires) to move the fingers.

-

The thumb servo is placed internally and programmed for complex motion (e.g., grip, grasp).

-

The system is calibrated initially to ensure that the sensor’s minimum and maximum bend corresponds accurately to servo limits.

-

Minor smoothing/filtering algorithms are used in the code to reduce jitter from sensor fluctuations.

🔹 5. Power Management

-

The servo motors are powered separately through a dedicated battery pack or power supply, as running them directly from Arduino can cause brownouts.

-

The Arduino boards and nRF modules are powered using regulated 5V sources with capacitors to maintain signal stability.

Project Titles

- Wireless Gesture Controlled Robotic Hand using Arduino and nRF24L01

- Arduino-Based Wireless Robotic Hand with Flex Sensors and Servo Motors

- 3D Printed Wireless Robotic Hand Controlled by Glove and nRF Module

- DIY Wireless Robotic Hand with Real-Time Flex Sensor Control

- Gesture Controlled Robotic Hand using Arduino, Flex Sensors, and nRF Modules

- Long-Range Wireless Robotic Hand using nRF24L01 and Arduino UNO

- Prosthetic Robotic Hand Project using Servo Motors and Flex Glove

- Arduino Wireless Robotic Arm with 5 Finger Control and Thumb Servo

- Wireless Robotic Glove and Hand System using nRF Modules and Flex Sensors

- IoT-Based Wireless 3D Printed Robotic Hand for Remote Operation

- Wireless Robotic Hand using RF Modules and Flex Input

- nRF-Controlled Arduino Robotic Hand with Gesture Recognition

- Robotic Hand for Prosthetics using Arduino and Flex Sensor Glove

- Arduino Project: Wireless Robotic Hand with MG995 and 9g Servo Motors

- Human Hand Controlled Wireless Robot using Glove and Arduino

wireless robotic hand using Arduino, Arduino robotic hand nRF module, nRF24L01 robotic hand, flex sensor robotic glove, gesture controlled robotic hand, Arduino MG996 servo hand, robotic arm using flex sensors, 3D printed robotic hand project, Arduino servo control hand, wireless gesture control hand, robotic hand for prosthetics, DIY robotic hand with Bluetooth glove, long range robotic hand RF module, Arduino wireless hand control system, flex sensor with voltage divider 10k, robotic hand with 6 servo motors, human hand imitation robot Arduino, robotic glove transmitter Arduino, gesture controlled 3D printed hand, Arduino nRF24L01 1km range project

========================

👉🚀 Don’t forget to SUBSCRIBE for more Science/ Diploma/ Engineering Projects !

========================

Get the full working project with components, code, diagrams & explanation

No branding on project, handmade look for students, and different styles as required by students.

To Buy/ Make this project with training

Contact us:

👨🏼🏭Dr. Vipin Kumar Sharma

Ph.D., M.Tech, B.Tech in ECE

🎓Lecturer 🚀#Researcher #Drone #Robotics

WhatsApp : https://wa.me/919810326343

Hindi/ English

✅🔥Follow us on

▶️YouTube 👥 Facebook 🐤 Twitter 📸 Instagram👨🏻🎓 LinkedIn

𝗔𝗯𝗼𝘂𝘁 𝗨𝘀 :

𝗫𝗶𝗟𝗶𝗥 𝗧𝗲𝗰𝗵𝗻𝗼𝗹𝗼𝗴𝗶𝗲𝘀™ is India’s 🔖Top rated & Leading R&D Company. It’s an ISO 9001:2008 Certified Company & Govt Approved under MCA & it was established in 2012.

Hi, guys if you want customizations in our projects you can contact us on WhatsApp us

Some Customization suggestions: Like IOT, Solar, Ml integration, Additional sensors, GPS GSM etc.

Reviews

There are no reviews yet.